Prototyping & Other Technologies

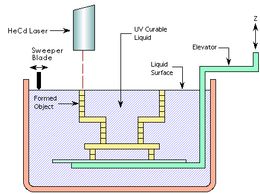

Sterolithography

SLA is Stereolithography.The SLA process uses a laser to build the part in a bath of liquid resin.

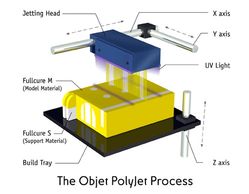

PolyJet Printing

The PolyJet Process uses ink jet technology to dispense special UV curable resins to form parts. This is the best technology for low durometer and multidurometer prototypes

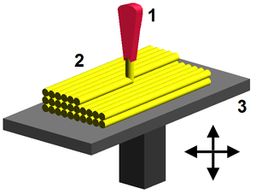

Fused Deposition Modeling

FDM is Fused Deposition Modeling. Hot plastic is extruded through a heated orifice or nozzle to form the part.

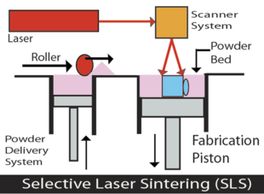

Selective Laser Sintering

SLS (Selective Laser Sintering) and DMLS (Direct Metal Laser Sintering) utilize laser technology to melt and bond either plastic (SLS) or metal (DMLS) particles to form the part.

Soft Tooling - Liquid Casting

Soft Tooling/Liquid Casting can be used with urethane and silicone resins to produce functional parts for prototype or production. Watch this video (below) for a good overview of the process.

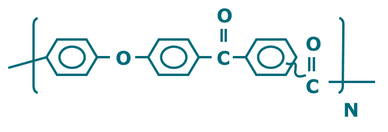

OXPEKK® Polymer

OPM’s OXPEKK ® formulations

provide exceptional physical properties

- Superior strength

- Excellent chemical resistance

- Tailored electrical properties

- 300 F to 300 F applications